Preventing damage and deterioration due to electrolytic corrosion also improved the functionality of the motor.

Couplings are necessary parts for connecting motors and sensors of industrial robots, etc.

Couplings are parts that connect the driving shaft and driven shaft, and have two main uses: power transmission and position control.

DPI manufactures Micro Couplings for the purpose of position control, which are used to connect between motors and sensors in industrial robots, etc. We were the first in Japan to manufacture and sell Micro Couplings in 1977, and our strength lies in the technological capabilities we have cultivated over many years.

In recent years, as inverter motors have become more popular and carrier frequencies have become faster, electrolytic corrosion of bearings due to current leaking from the motor has become an issue. Electrolytic corrosion accelerates the corrosion and deterioration of bearings, which not only causes misalignment, but also affects reducers and detectors.

One company introduced tire couplings made of rubber to prevent electrolytic corrosion. However, there were many cases where the rubber was too hard and the detector shaft broke, or the bearings were damaged due to the inability to center the detector.

However, because the rubber was too hard, there were many cases where the detector shaft broke or the bearings were damaged due to difficulty in centering.

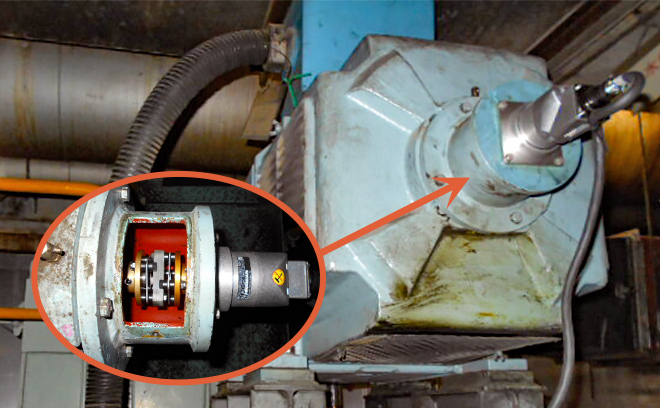

Contributing to extending product life by introducing electrically insulated Micro Couplings

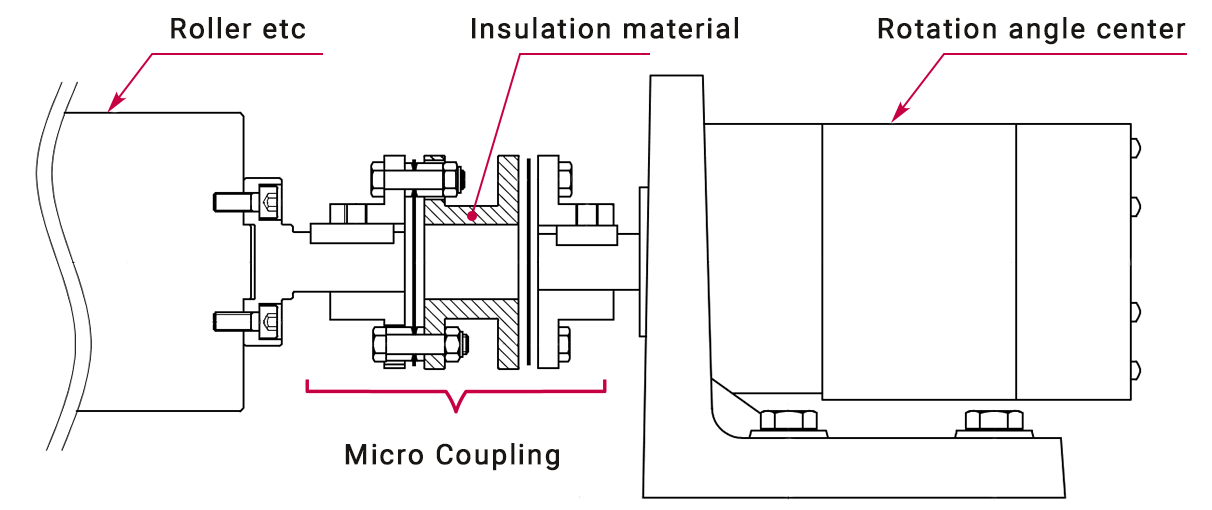

We have developed an electrically insulated Micro Coupling that applies the technology of the FORM-FLEX electrically insulated coupling, which has a proven track record of being used in the drive parts of paper-making machines. By using an insulating material in the intermediate spacer part of the Micro Coupling, we have blocked the leakage of shaft current from the motor. As a result, we have achieved a significant reduction in damage and erosion caused by electrical leakage, reduced maintenance costs to extend product life, improved power efficiency by preventing current leakage, and improved motor functionality.

As electrification progresses, the use of electrically insulated Micro Couplings is increasing. Therefore, we will continue to strive to develop couplings that provide the desired functionality by taking advantage of the characteristics of various materials.