We have contributed to proposing appropriate materials, extending product life, and reducing costs.

Compressors are devices with a wide range of uses, from automobiles to industrial machinery.

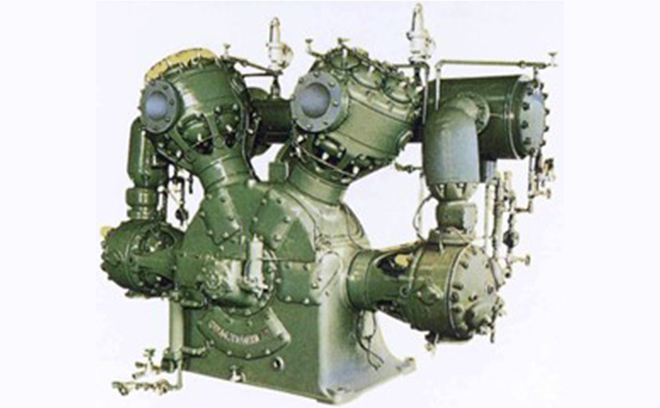

Since its founding, DPI has been involved in manufacturing valves for reciprocating compressors that compress fluid through the vertical movement of pistons.

Initially, the issue was the product life of the valve. Valves that have a large amount of movement are subject to rapid wear and tear, and they typically last 2,000 hours at full operation, with a maximum of 4,000 hours, requiring parts to be replaced approximately once every three months.

Therefore, we considered materials and proposed stainless steel containing chromium. Chromium forms a thin film on the surface of the material to prevent rust.

This membrane is extremely durable, and even if it breaks, it can be regenerated if there is oxygen around it.

We use materials that can withstand outdoor conditions, and we have increased the strength through heat treatment to withstand intense movement.

Issues

- Valve wears out rapidly, so parts need to be replaced approximately once every three months.

- It is necessary to extend the life of parts and reduce the frequency of replacement.

Grinding improves flatness accuracy and doubles product life.

The thin plates used in valves must have extremely high flatness to prevent fluid leakage. Heat treatment causes distortion in the material, so subsequent flattening is essential.

Since our company has a vertically integrated production system, we also have advanced technology for surface grinding. In addition to meeting strict flatness accuracy, we can also grind even the hardest materials. Therefore, we can manufacture highly durable thin plates using stainless steel.

We have now extended the product lifespan to 8,000 hours, thus reducing costs by requiring less frequent replacement.

In the future, we will develop our thin plate technology and consider expanding it to other industries.

Function

A reciprocating compressor uses the reciprocating motion of a piston inside the cylinder to suck air into the cylinder, compress it, and then discharge it. Our products are used in the suction and discharge valves, which are vital to reciprocating compressors.