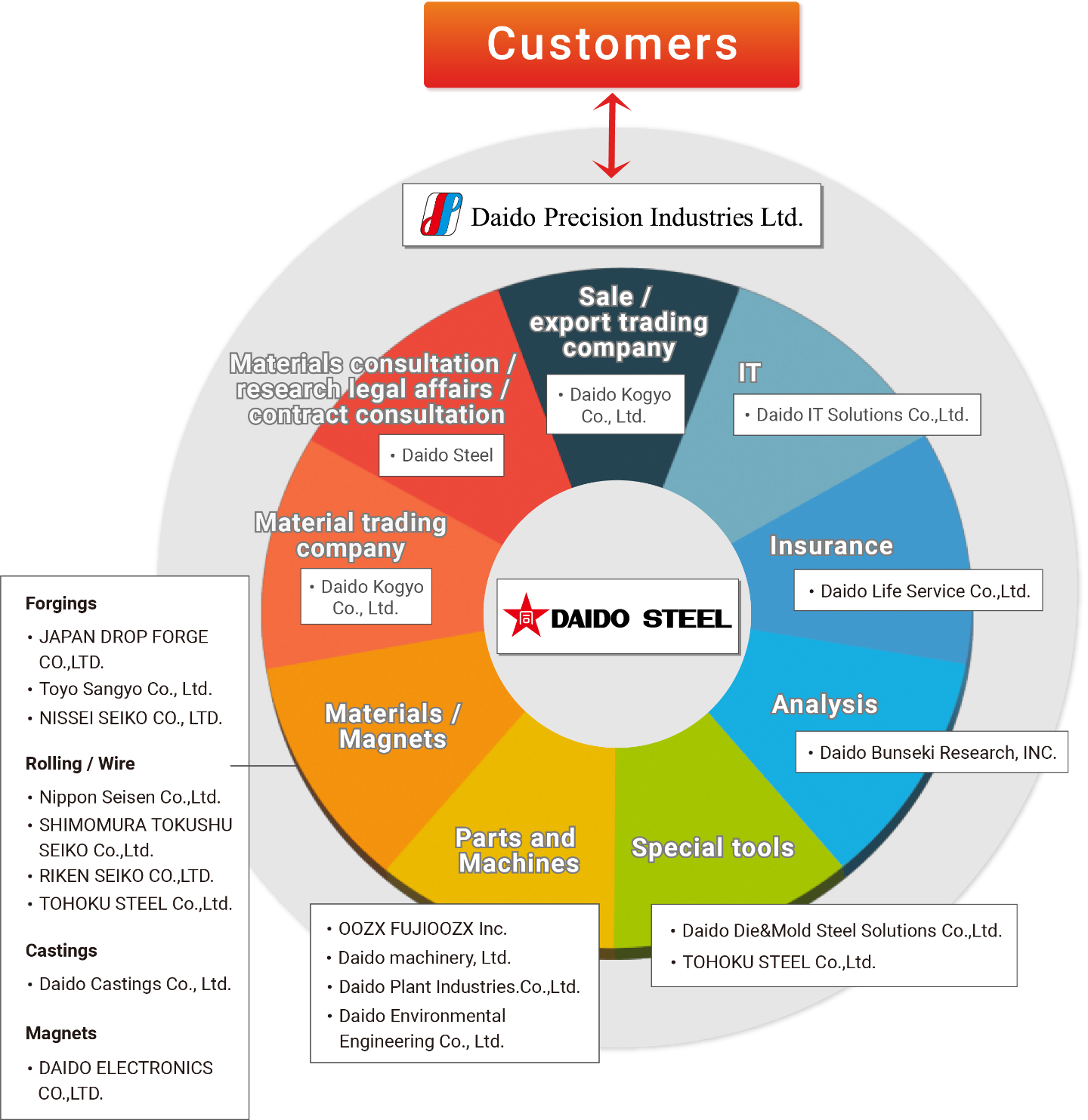

As a group company of Daido Steel, we have the strength of being able to procure all kinds of materials.

In addition, we are able to respond to the various requests of our customers using the technical capabilities and proposal capabilities that we have cultivated over many years.

About Daido Precision Industries Ltd. (DPI)

Established 90 years ago, we began by manufacturing valve plates, and have mainly been processing precision metal parts.

We have leveraged our strength as a member of the Daido Steel Group to respond to changes in the world and customer needs.

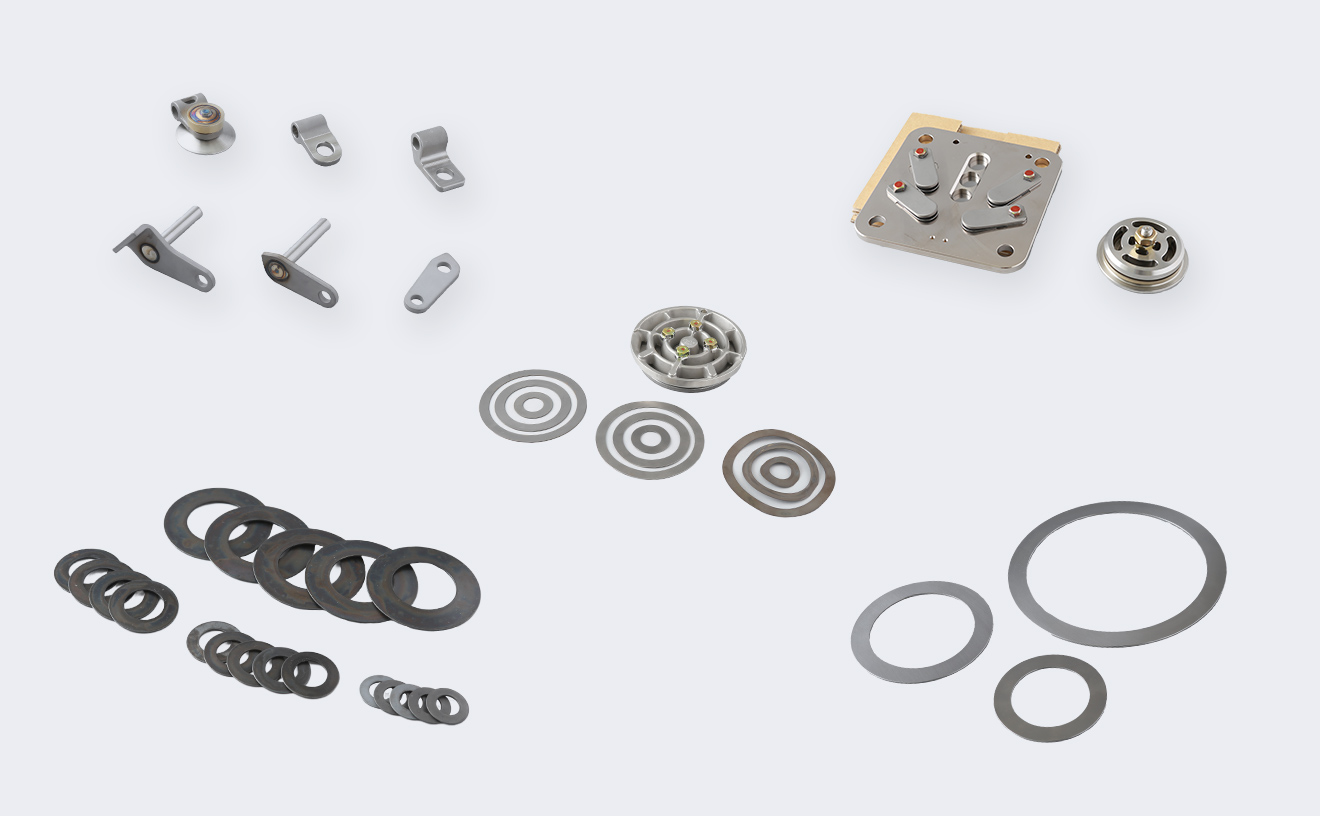

Our main businesses are our “parts business” and “coupling business.”

Features of parts business

The parts we manufacture are characterized by superior design and machining of difficult-to-machine high-alloy materials.

Our thin plate-shaped disc springs and industrial machinery parts are packed with the functionality requested by our customers and the design and manufacturing know-how to ensure stable use over long periods of time. Automotive parts require heat resistance and durability, and often use high alloys that are difficult to process. We make full use of our knowledge and know-how to make proposals regarding processing methods, shapes, etc. as needed.

In recent years, we have also been focusing on precision processing of magnets, which are said to be brittle and difficult to process.

Our technology can also be used to process materials with opposite properties, such as hard and difficult to cut, brittle and difficult to cut, etc.

Features of the coupling business

Couplings are essential for power transmission. They are used in all industrial fields such as steel manufacturing, machinery, and semiconductors.

Leveraging our strength as the first manufacturer in Japan to have introduced metal plate spring (flexible disc) technology, we design and process products according to customer requests.

In addition to packaged products, we also handle the design and processing of couplings for automotive testing systems, each with a different shape. In other words, we are good at high-mix low-volume production.

As a Daido Steel company

As a group company of Daido Steel, we have knowledge of a wide variety of materials, so our strength is that we can propose and provide materials that meet customer needs.

There are a variety of materials, including cast materials, forged materials, plate materials, and magnetic materials. Since we specialize in each type of manufacturing, we have the expertise to respond to a wide variety of requests. As our group includes trading companies, we are able to procure materials and collect information worldwide, even for materials that cannot be procured within our group. In addition, in a market that is undergoing rapid change these days, one of our strengths is that we “adapt well to change,” as we share marketing information within our group. We are developing technologies and materials that match the times.

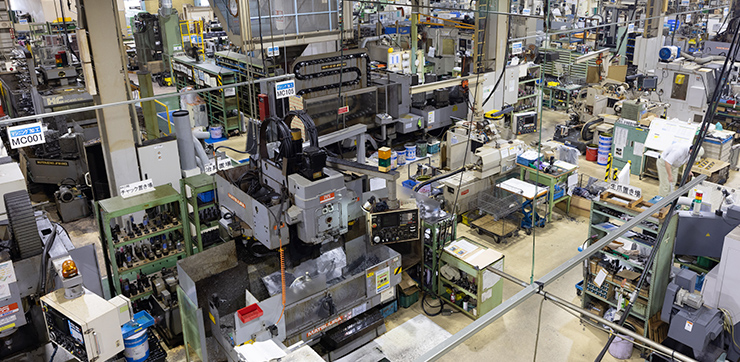

DPI’s manufacturing

We believe that the features of DPI’s manufacturing are “technical and proposal capabilities,” “vertically integrated production system,” and “quality assurance.”

Based on diagrams provided by the customer we consider materials, quality, and processing technology. We consider quality, cost, etc. from multiple angles, and propose materials and processing methods with the aim of producing better products. We strive to create products that go beyond the diagrams.

Once the customer agrees to the diagrams, we will arrange the materials. With the cooperation of group companies, we arrange the necessary materials and proceed to processing.

For processing, we can provide integrated production from pressing, cutting, and grinding to heat treatment, surface treatment, and final finishing. We believe that for our customers, there is no need to have multiple suppliers for each process, and the process can be completed with just one supplier, which is a great advantage in terms of quality and cost.

For us, as we can proceed with the work while sharing information in each process, mistakes are less likely to occur and we are able to respond in detail to quality control.

Additionally, since we primarily deal with automobile-related parts, we are required to meet strict quality assurance standards.

We have acquired IATF16949 certification, an international quality standard, and meet strict quality requirements with an inspection system that follows the manual.