What is DPI' parts business?

It can process a wide variety of materials in precision machining.

The major features of our company are its high level of “technical capabilities and proposal capabilities,” “integrated production,” and “quality assurance.”

DPI is a group company of Daido Steel, and its main business is precision machining of parts.

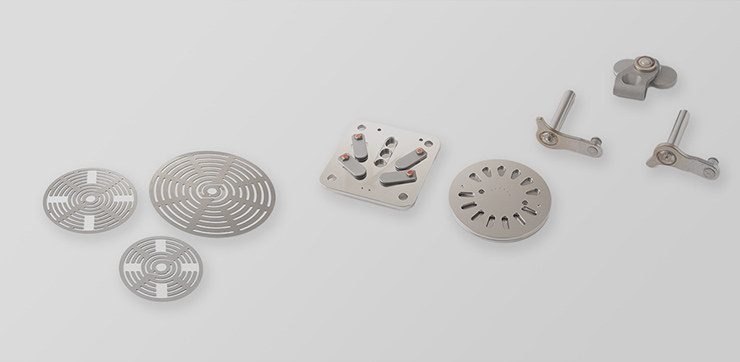

When we first started our business, we manufactured thin plates such as valve plates. We have further refined our technology to meet the diverse needs of our customers. As a result, our strength now lies in our ability to handle materials that are difficult to process, such as heat-resistant steel and high alloys.

Automotive-related parts, mainly turbocharger parts, now account for the majority of our sales. However, as automobiles are undergoing a period of transformation, we are working on developing new technologies based on the processing technology we have cultivated over the years, and are also taking on challenges in new fields.

Features of DPI parts

Our strength is our ability to make proposals regarding materials and processing. In addition, we are particular about creating products that go beyond the customer's diagrams.

A major feature of our company is our ability to propose materials and processing that meet customer requests.

If you have any trouble selecting the material for your products, feel free to contact us. With the support of Daido Steel, a material expert, we can propose materials with material properties that meet your needs.

Regarding processing, we examine the material shape and processing process in-house based on the diagrams provided by the customer. Then, we propose near-net-shape changes to materials and partial changes to product shapes in order to reduce costs and improve quality. In order to further satisfy our customers in terms of quality and cost, we strive to create products that exceed the customer's diagrams.

Even if your processing requirements cannot be handled with our own equipment alone, we will be able to handle them with the cooperation of Daido Steel Group companies and partner companies.

Therefore, we can meet your needs with integrated production from material procurement to product completion.

We can propose solutions that leverage the strengths of the Daido Steel Group, including material procurement.

Utilizing the technology and knowledge of group companies, we can handle difficult materials and processing.

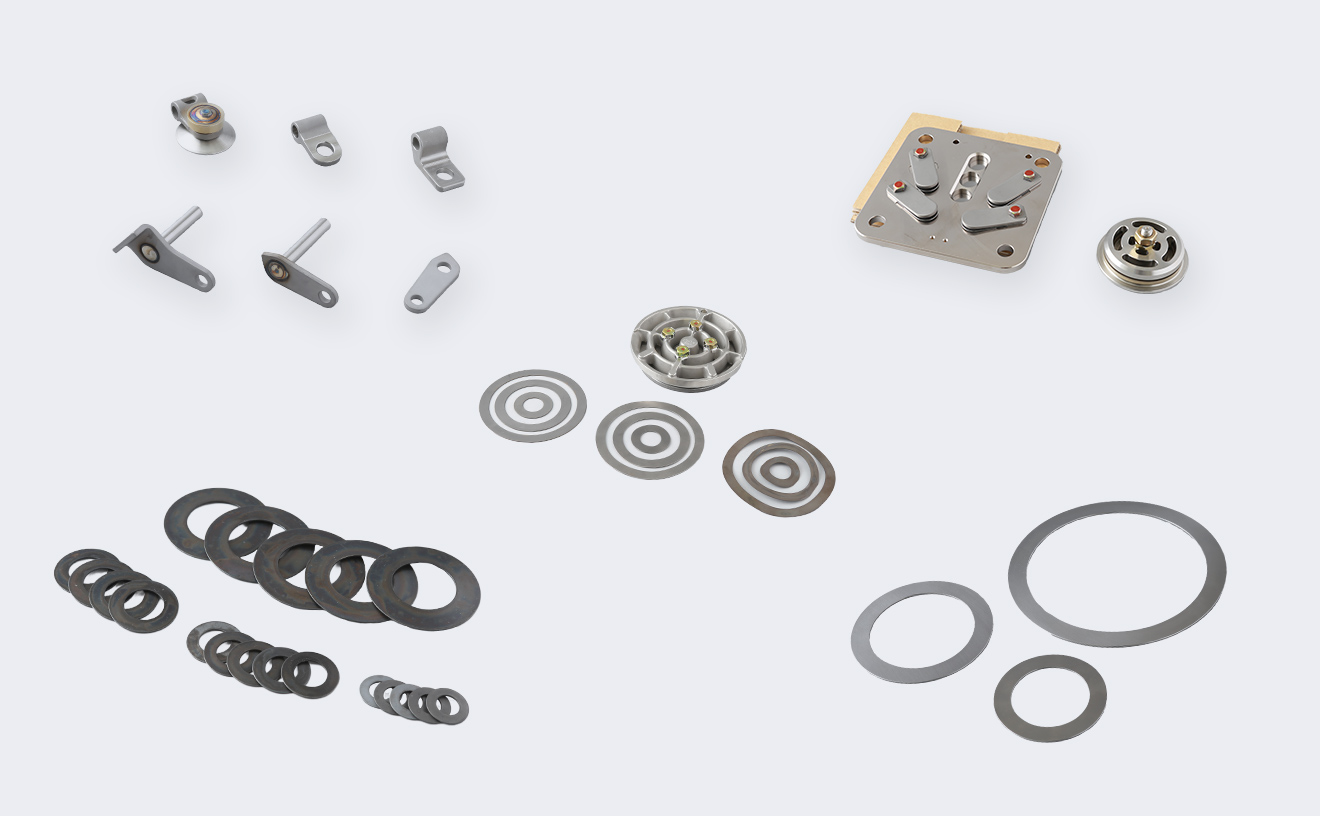

We mainly handle materials such as general steel material, high alloys including nickel and titanium, and stainless steel. We can also supply processed materials such as plates, bars, forgings, and castings. If you require more detailed knowledge about materials, we ask for cooperation from group companies that have their own specialties.

Regarding processing, we can handle not only lathe turning and MC processing, but also barrel polishing and lapping, various heat treatments, and nitriding treatments. We offer a wide range of services, from riveting and welding to assembly, in response to customer requests.

What is noteworthy is that, as a group company of Daido Steel, we are able to procure materials that are difficult to obtain and can process difficult-to-cut materials. In addition, we can not only procure materials from Daido Steel, but also obtain information about the materials, so we can process them to suit their characteristics.

Recently, we can also process magnets that are hard and brittle, and which are difficult to process.

For this type of processing, we can receive advice from companies within our group that handle magnets. Therefore, we aim to create products that meet the required performance by leveraging our experience in machining difficult-to-cut materials and verifying various machining methods.