High performance materials and parts are required to help reduce environmental impact and improve fuel efficiency.

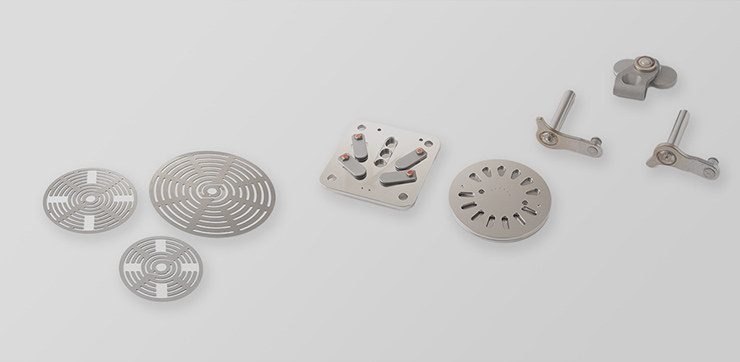

Passenger vehicle (gasoline engine) turbocharger parts

We manufacture heat-resistant, high-alloy wastegate valve-related parts that can contribute to increasing engine efficiency and reducing CO2 emissions.

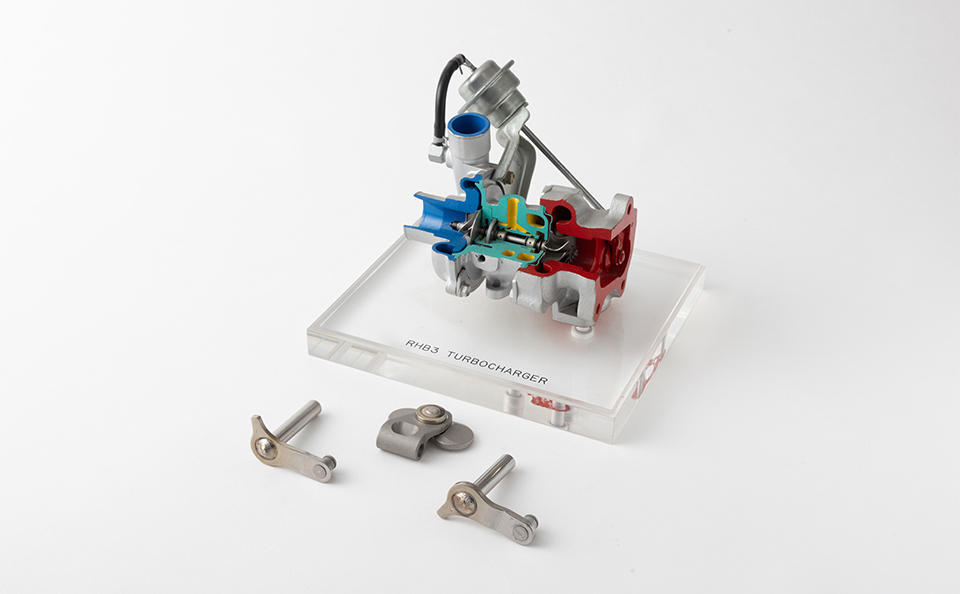

A turbocharger is a device that uses engine exhaust gas to turn a turbine wheel and send compressed air to the engine (supercharging).

We manufacture wastegate type turbocharger parts for gasoline engines for passenger vehicles and variable geometry turbocharger parts for diesel engines for commercial vehicles such as trucks.

Each turbocharger has different challenges.

Regarding passenger vehicles, efforts are currently underway to reduce CO2 emissions from vehicles worldwide.

One of the countermeasures is to reduce the weight of vehicles. Among these, it is effective to reduce the weight of heavy engines by downsizing them and reducing their displacement.

On the other hand, from the standpoint of comfort inside the vehicle, it is difficult to make the vehicle itself smaller because it may reduce the product value.

An engine that is smaller or has a smaller displacement will lack power when running a vehicle of the same size as before. Therefore, a turbocharger is installed to supplement the power.

Gasoline engines have high exhaust temperatures, so the exhaust system parts of turbochargers must be made of heat-resistant high alloys that can withstand these temperatures, but the problem with such materials is that their cutting processing is difficult. DPI is good at processing such heat-resistant high alloys. Specifically, we provide valves and related parts for turbocharger wastegate mechanisms that release excess exhaust gas with high processing precision.

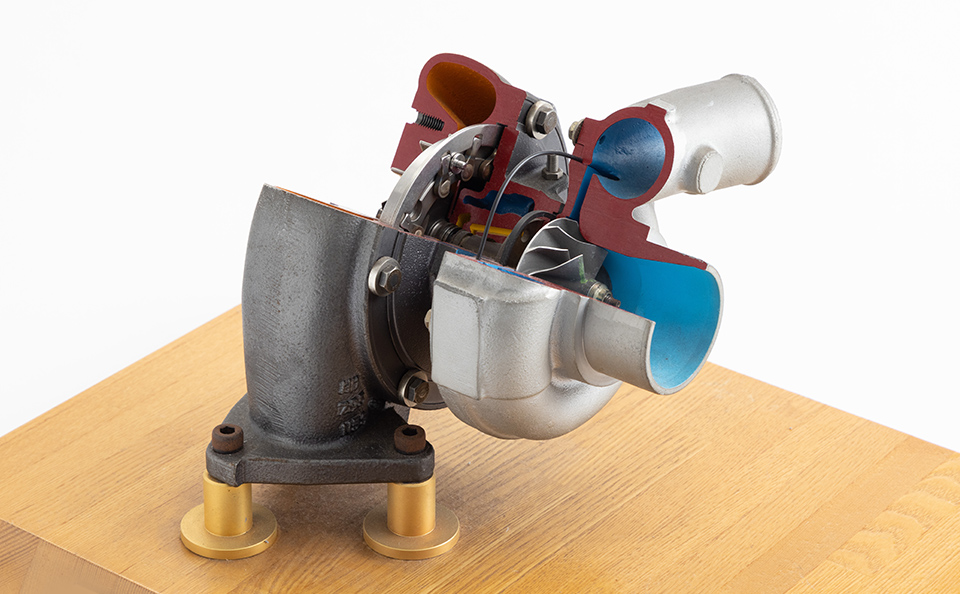

Turbocharger parts for commercial vehicles (diesel engines)

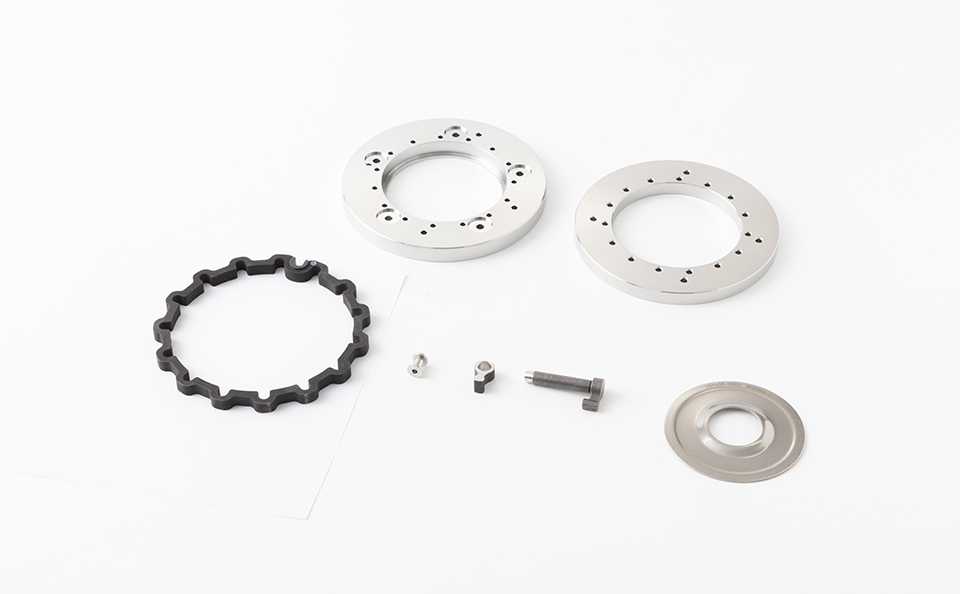

The parts we manufacture are related to the opening and closing of variable geometric valves that adjust the exhaust gas flow rate.

Turbochargers for commercial vehicles (diesel engines) not only increase power, but also contribute to reducing environmental impact.

Environmental pollutants such as NOx and PM have a trade-off relationship: NOx is emitted at high temperatures, and PM is emitted at low temperatures.

How to adjust these emissions was a major issue for turbochargers for commercial vehicles (diesel engines).

Turbochargers for commercial vehicles (diesel engines) need to appropriately adjust the gas flow velocity from low to high cycle of engine. Therefore, a variable turbocharger is used, which has a variable mechanism to adjust the gas flow rate.

DPI manufactures parts related to opening and closing the valves of this variable mechanism.

It is a part that slides without lubrication and is exposed to high temperatures. Therefore, smooth surface texture and high dimensional accuracy are required to improve wear resistance.

We also handle parts that require surface treatment such as nitriding and assembly.

Rather than using high-grade, high-alloy materials, we produce parts that use surface treatments to achieve the necessary corrosion and wear resistance.

We deliver products that have been surface treated by our partner companies. Nitriding is often used to improve wear resistance. Regarding nitriding, we have an in-house gas nitriding furnace and can perform gas nitriding in-house.

It is also possible to weld and rivet the manufactured parts, join them, and assemble them (sub-ASSY) before delivery.

We are characterized by integrated production from material procurement to product completion. Please feel free to contact us.