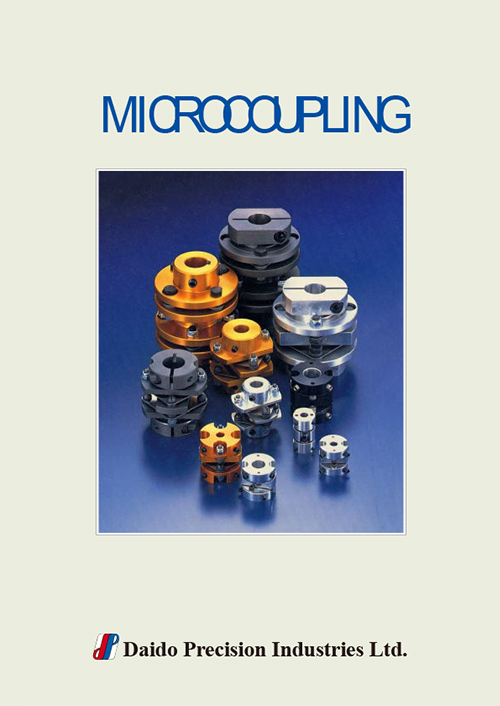

What is Micro Coupling?

That is Japan's first compact size plate spring (flexible disc) coupling. Plate springs, which are vital to the couplings, are derivative from our sheet metal fabricating technique, the expertise unique to us being cultivated for nearly half a century.

Since its launch in 1975, we have accumulated a wealth of experience and achievements. Nowadays, Micro Coupling is recommended and used in a wide range of cutting-edge fields such as measuring instruments, machine tools, robots, and semiconductors.

With a wide product lineup from high-precision and high-torque products to low-torque and general-purpose products, a vertically integrated production system from design to manufacturing and inspection, and stable quality, we provide products that meet the needs of the times.

Our couplings are called Form-Flex couplings for torque transmission of 33.3 N・m or more, and Micro Couplings for torque transmissions of less than 33.3 N・m.

Features of Micro Coupling

Feature 1. Backlash-free

- Each component is mechanically connected, allowing precise rotational control.

Feature 2. High torsional rigidity

- Utilization of resiliency, a property of metal plate springs (flexible disc), provides high resonance frequency and precise responding characteristic.

Feature 3. Greater torque capacity

- Transmission of torque developed by metal plate springs (flexible disc) as simple tensile force allows for provision of greater torque capacity as compared to those using shearing force.

- Use of high-tensile steel metal plate springs (flexible disc) provides tenacity against intense right and reverse rotation.

Feature 4. High power for absorbing parallel and angular misalignment

- High fatigue resistance of metal plate spring (flexible disc) allows for provision of a high power for absorbing eccentricity and angular misalignment.

- Increasing distance between metal plate spring (flexible disc) allows for making higher power for absorbing parallel misalignment without changing torsional rigidity, thus facilitating centering.

Feature 5. Long life with no maintenance required

- Having no sliding parts eliminates wear, thus allowing continuous operation for extensive period of time without lubrication.

Feature 6. High degree of freedom for each part

- Connecting respective parts based upon machine elements allows changes in parts composition, thus meeting all needs arising depending upon application.

Application examples of Micro Coupling

- Connecting a motor shaft and rotation detector such as for servo motors.

- Driving feed screws in NC machine tools, industrial robots and the like.

- Precision positioning in X-Y tables, measuring instrument, office automation equipment, semi-conductor processing units and the like.

Micro Coupling catalog download

Download